Tehnologije 3D tiskanja

Različne tehnologije 3D tiskanja omogočajo rešitve za številne aplikacije. Izdelava domačih pripomočkov, zahtevnih inženirskih delov, prototipov ali kosov v manjših serijah – možnosti 3D tiskanja, tudi zaradi številnih tehnologij, so skoraj neskončne. Zaradi odlaganja plasti materiala lahko izdelamo praktično katere koli oblike predmetov.

Prednost 3D tiskanja je neposredna izdelava izdelkov iz CAD modela brez uporabe kalupov ali orodij. Gre namreč za aditivni postopek, pri katerem se nalagajo zaporedne plasti materiala. Na takšen način lahko najhitreje in cenovno najbolj ugodno pridete do fizičnih modelov. Pri 3D tiskanju je zaradi nalaganja, ne odvzemanja, odpadnega materiala bistveno manj.

NAJBOLJ POGOSTE TEHNOLOGIJE 3D TISKANJA...

- FDM (Fused Deposition Modeling),

- SLA (Stereolithography),

- DLP (Digital Light Process),

- SLS (Selective Laser Sintering),

- SLM (Selective Laser Melting),

- MJ (Material Jetting),

- DED (Directed Energy Deposition),

- LOM (Laminated Object Manufacturing)

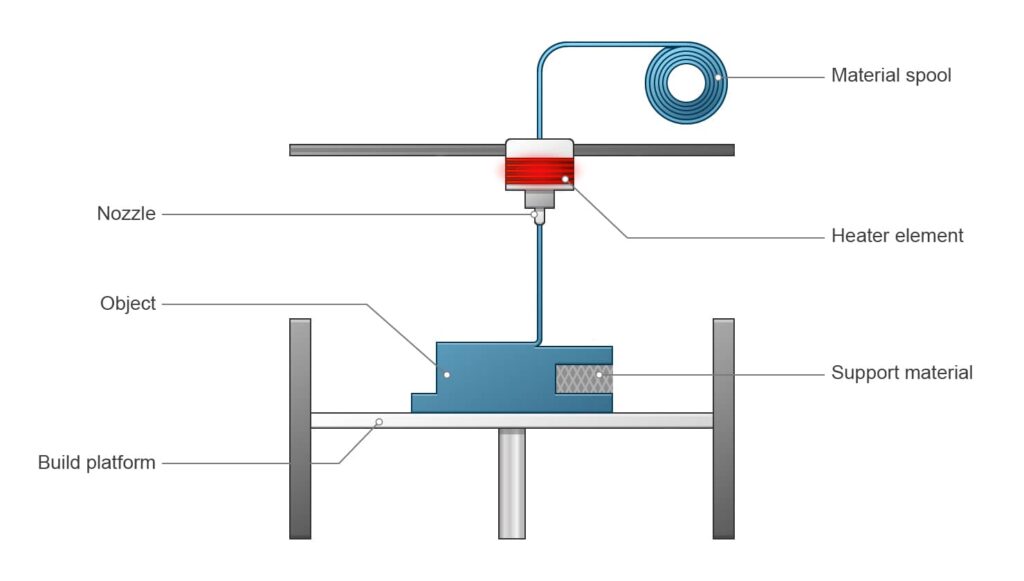

1. FDM – FUSED DEPOSITION MODELING

Najbolj razširjena tehnologija 3D tiskanja za široko paleto uporabnikov. 3D tiskalnik v ekstruder vleče filament, kjer ga topi in preko šobe nanaša na delovno površino. Tam se ohladi in strdi. S programiranimi in preciznimi premiki glave tako nastane končni izdelek.

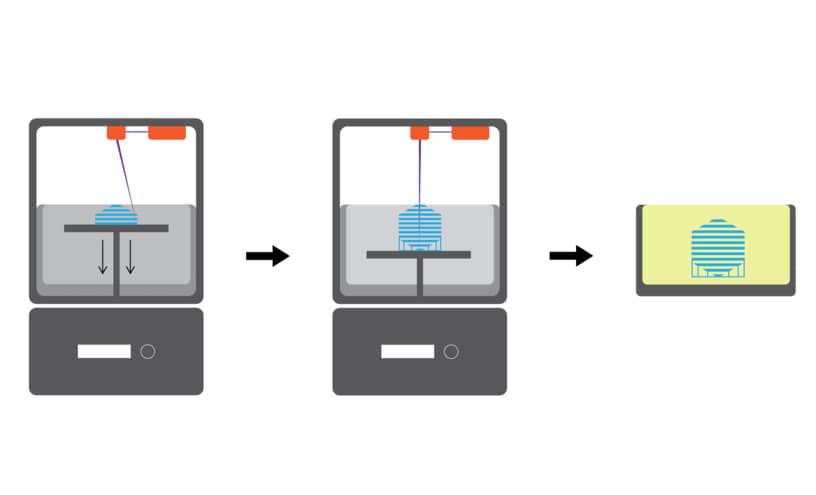

2. FOTOPOLIMERIZACIJA (SLA & DLP)

Najbolj pogosti sta SLA (Stereolithography), ki je prva v zgodovni, in DLP (Digital Light Processing). SLA je nekoliko natančnejša metoda, saj z uporabo laserja deluje bolj točkovno, s čimer je primernejša za izdelavo manjših kosov. Vir svetlobe s pomočjo ogledal na X in Y osi prodre skozi posodo s smolo, katero selektivno strjuje po plasteh. DLP tehnologija 3D tiskanja pa uporablja projektor, ki ima širši snop svetlobe. Kos je sicer izdelan hitreje, vendar ne s takšno natančnostjo, zato se to metodo uporablja za izdelavo večjih kosov. Obe tehnologiji sta pogosto uporabljeni v zobozdravstvu in zlatarstvu.

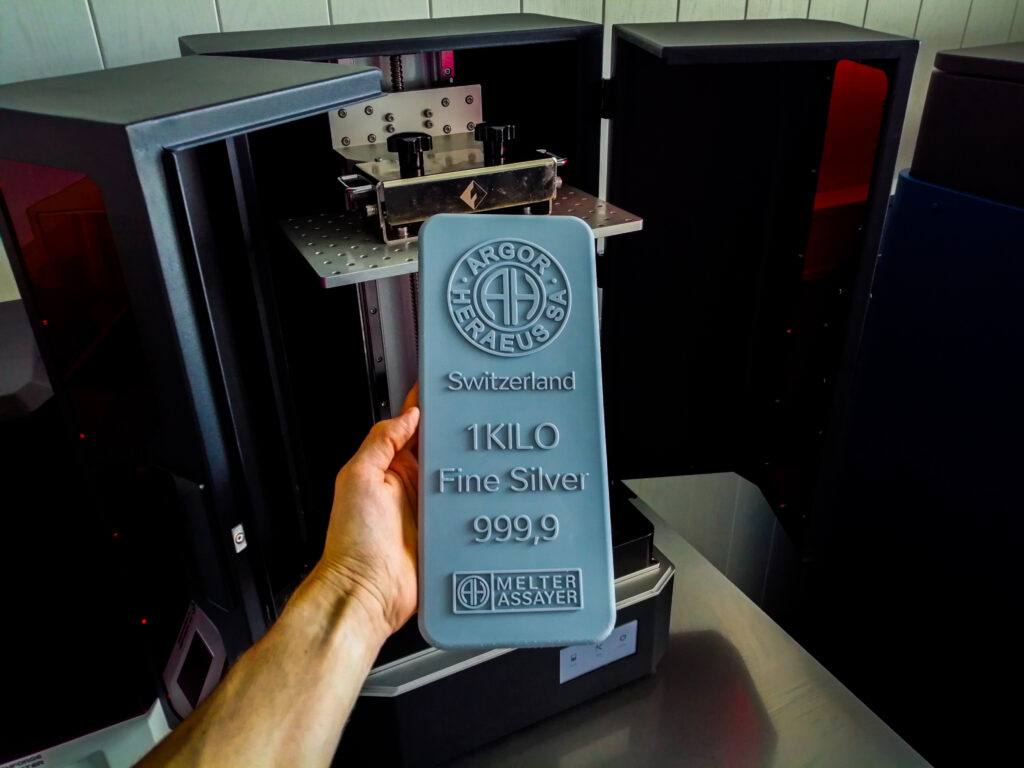

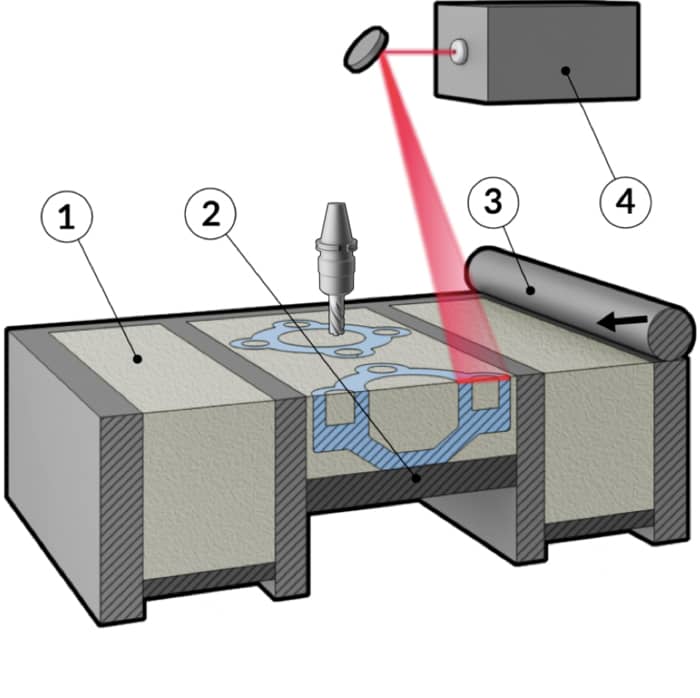

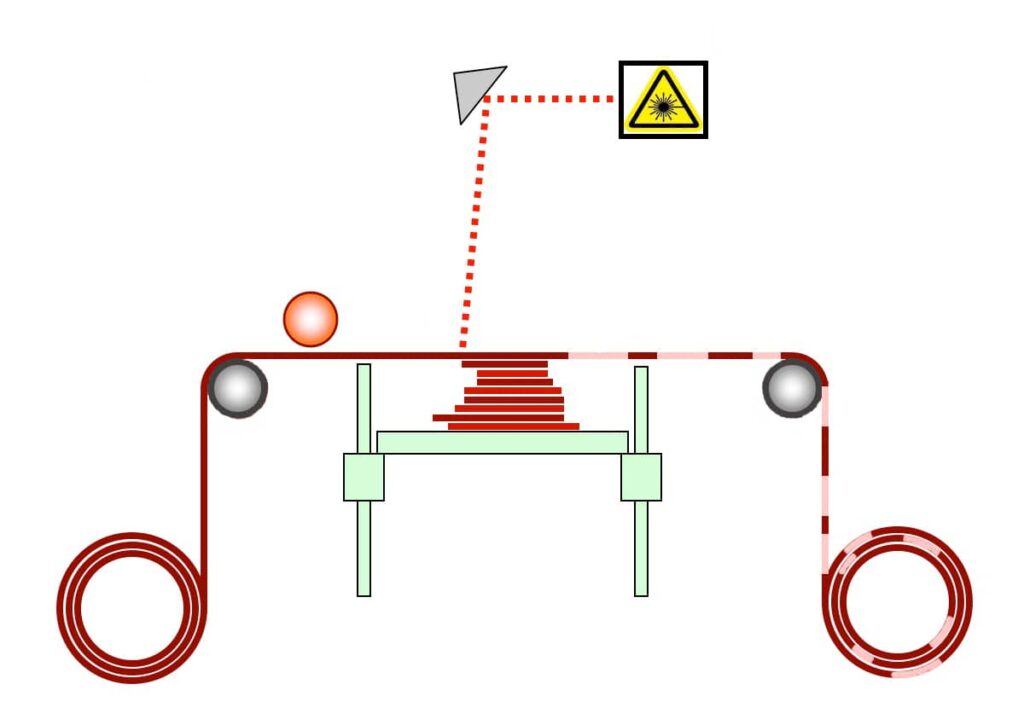

3. LASERSKA TEHNOLOGIJA (SLS & SLM)

Laserska tehnologija 3D tiskanja za “gradbeni” material uporablja prah, ki ga laser nanaša po posameznih slojih. Ob izpostavljenosti snopu, se temperatura praha dvigne nad temperaturo kristalizacije, kar spoji sloje. Laserski tehnologiji sta dve, in sicer SLS (Selective Laser Sintering), ki je namenjena tiskanju plastičnih kosov, ter SLM (Selective Laser Melting), ki omogoča 3D tisk kovinskih kosov.

4. MJ – MATERIAL JETTING

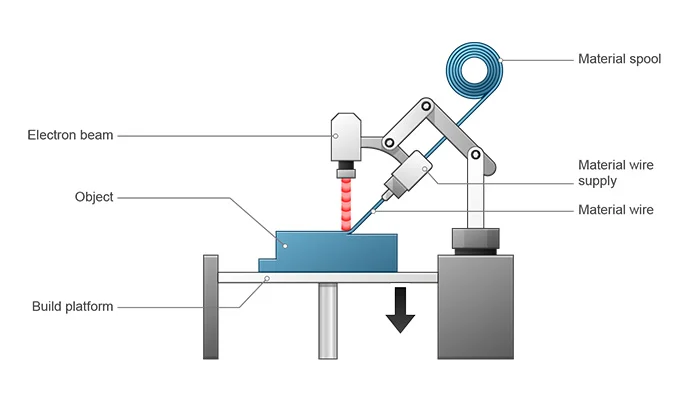

5. DED – DIRECT ENERGY DEPOSITION

6. LOM – LAMINATED OBJECT MANUFACTURING

RAZLIČNE TEHNOLOGIJE 3D TISKANJA ZA RAZLIČNE POTREBE

Vse naštete tehnologije 3D tiskanja znotraj svojih omejitev ponujajo širok spekter naprednih rešitev. 3D tiskanje se zelo hitro razvija in omogoča uporabnikom učinkovite rešitve.

Največje koristi in prednosti 3D tiskanja:

- Hiter čas izdelave in nizki stroški pri razvijanju določene ideje,

- Odpravljanje napak pri zgodnjih fazah razvoja izdelka,

- Preverjanje dimenzijske ustreznosti, oblike, funkcionalnosti in ergonomije,

- Optimizacija izdelka pred izdelavo orodja.