3D tiskalniki

- 3D tiskalniki za vsakogar

- 3D printerji vseh tehnologij (FDM, SLA, SLS, DLP, SLM)

- Od vstopnih do industrijskih 3D tiskalnikov

- 3D printanje plastike in kovine

VEČ O 3D TISKALNIKIH

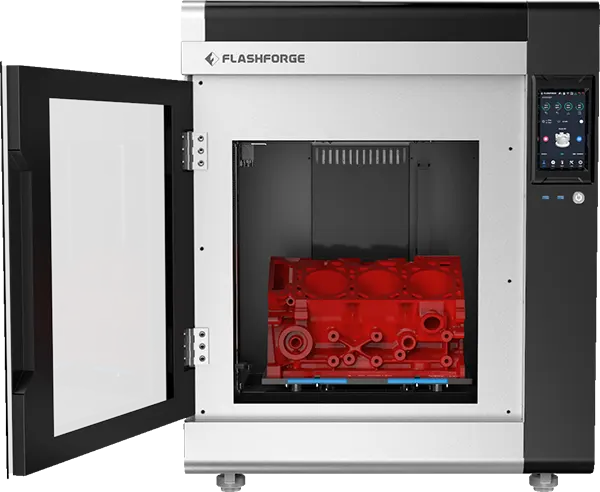

3D tiskanje je postopek izdelave trirazsežnih objektov iz digitalnega (CAD) modela. 3D tiskanje omogoča izdelavo izjemno kompleksnih oblik. Gre za aditivni postopek, pri katerem se v različnih oblikah zaporedno odlagajo plasti materiala. S tem se razlikuje od tradicionalnih proizvodnih tehnik, kjer gre za odstranjevanje materiala z metodami, kot sta rezanje ali vrtanje (subtrakcijski postopki).

3D tiskalniki običajno izvajajo procese 3D printanja z uporabo digitalnih tehnologij. Od začetka 21. stoletja se je prodaja 3D printerjev močno povečala, njihova cena pa je močno padla.

Tehnologija 3D tiskanja se uporablja za hitro izdelavo prototipov in proizvodnjo različnih izdelkov ali polizdelkov na področju zlatarstva, obutve, industrijskega oblikovanja, arhitekture, inženirstva in konstrukcije (AEC), avtomobilske, letalske in vesoljske industrije, dentalne in medicinske industrije, izobraževanja, geografskih informacijskih sistemov, gradbenega inženirstva ipd.

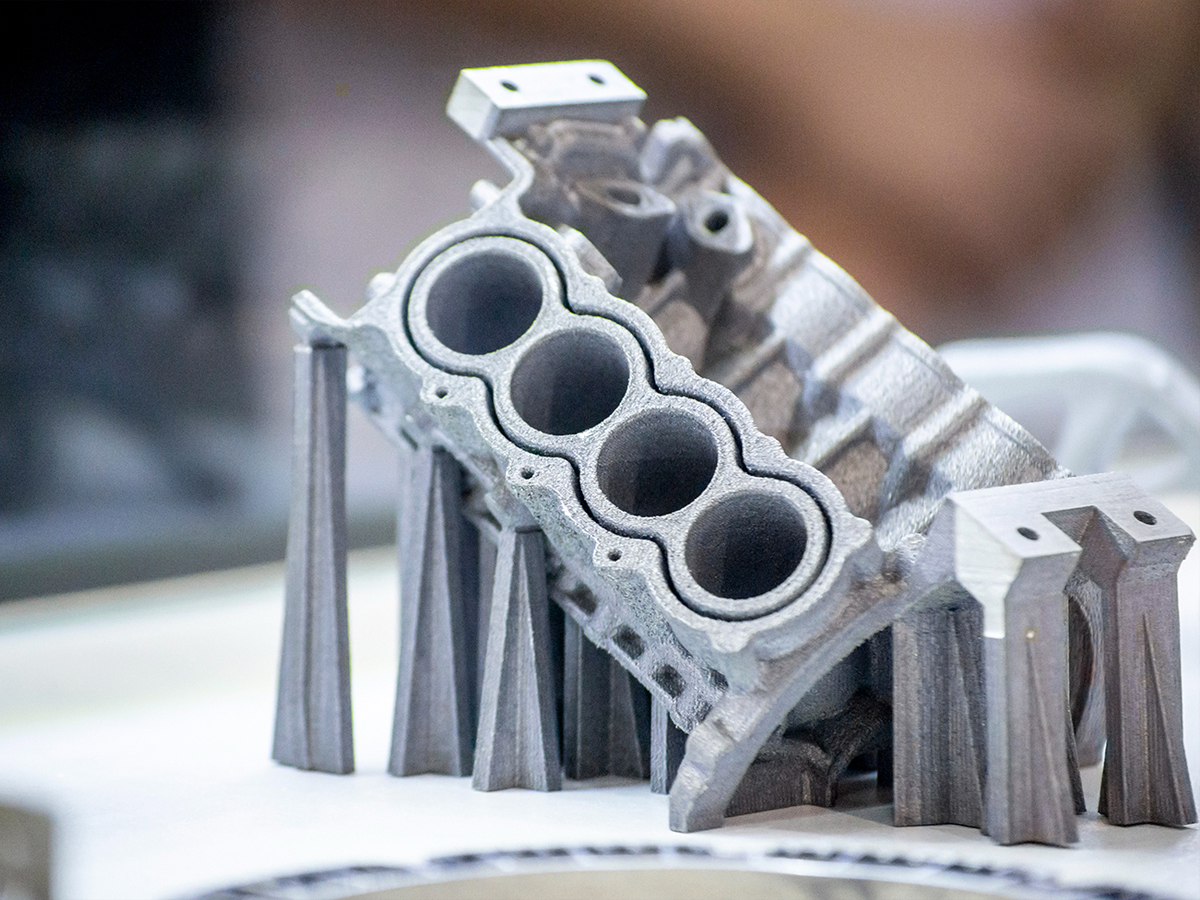

3D tiskalniki lahko za 3D printanje uporabljajo veliko različnih materialov (npr. guma, plastika, prah, smola, poliuretanski materiali, kovine in podobno), izbira pa je odvisna od zmogljivosti in tipa. V splošnem se materiali po plasteh nanašajo na različne načine, najpogostejši izmed njih pa je nanos taljenega polimera skozi majhno šobo.

Polimer je v večini primerov taljena plastika z ugodnimi lastnostmi za taljenje in hlajenje (v angleščini se uporablja bioplastika PLA ali bolj vzdržljiva ABS, ki za uporabo potrebuje ogrevano površino za nanos). 3D printerji med delovanjem vlečejo filament v ogrevano glavo (ekstruder), kjer se tali in ga nato skozi šobo nanašajo na delovno podlogo ali printano podlogo (raft).

Medicina

Dental

Potrošniški produkti

izobraževanje

Namen uporabe 3D tiskalnikov

- proizvodnja kompleksnih delov

- hitra izdelava prototipov

- redki zervni deli

- šablone in vpenjalni elementi

- prilagajanje izdelkov

- medicinski pripomočki

- izdelki za domače gospodinjstvo

GLAVNE PREDNOSTI, KI VAM JIH ZAGOTOVI 3D TISKALNIK

Hitrost in poenostavitev proizvodnega procesa:

Glavna prednost aditivne proizvodnje. Kompleksni deli in dizajni so lahko sprintani hitreje kot izdelani s klasično proizvodnjo. Večina delov v tradicionalnem proizvodnem procesu potrebuje veliko korakov, pri 3D printanju pa se CAD modeli naložijo neposredno v 3D tiskalnik in izdelajo v nekaj urah. S tem ideje hitreje prenesete v realnost.

Svoboda pri dizajniranju:

Omejitve pri klasični proizvodnji nimajo vpliva na 3D printanje, saj so komponente narejene po sistemu “sloj po sloj”. Tako lahko sprintate karkoli želite.

Brez odpadnega materiala in napetosti v kosu:

Pri obdelavi z odvzemanjem nastaja odpadni material, ki ga zatem zavržemo. Pri 3D printanju pa se material dodaja, s čimer bistveno zmanjšamo količino odpadkov in zmanjšamo stroške nabave materiala. Kasnejše varjenje pogosto povzroča dodatne napetosti v kosu, pri 3D printanju pa slednjih ni.

FAQ - 3D PRINTERJI IN 3D PRINTANJE

3D printanje je postopek izdelave trirazsežnih objektov iz digitalnega (CAD) modela. Omogoča učinkovito in hitro izdelavo izjemno kompleksnih oblik. Gre za aditivni postopek, pri katerem se v različnih oblikah zaporedno odlagajo plasti materiala, s čimer se razlikuje od tradicionalnih proizvodnih tehnik, kjer gre za odstranjevanje materiala z metodami.

3D printanje ponuja veliko rešitev na številnih področjih. Aplikacije 3D printanja so zaradi malo omejitev široko razsežne:

- Izdelava prototipov: hitra proizvodnja realnega kosa iz CAD modela

- Izdelava funkcionalnih 3D delov: funkcionalni deli z izjemnimi mehanskimi lastnostmi

- Medicina: izdelava protez, implantantov in celo organov

- Umetnost in dizajn: ustvarjanje unikatnih predmetov

- Izobraževanje: učenje o 3D tehnologiji

- Letalska industrija: izdelava lahkih in redkih komponent

- Avtomobilska industrija: izdelava rezervnih delov, kalupov, prototipov

Ob vstopu v svet 3D printanja prej ali slej začnete razmišljati, kateri filament za 3D printanje potrebujete. Tukaj je nekaj najbolj pogosto uporabljenih:

PLA (Polylactic Acid): biološko razgradljiv material rastlinskega izvora. Ima najmanjše zahteve in je enostaven za 3D tiskanje. Kompatibilen s široko paleto 3D printerjev.

ABS (Acrylonitrile Butadiene Styrene): odlične mehanske lastnosti – odporen na višje temperature in UV-svetlobo.

PETG (Polyethylene Terephthalate Glycol): zmes PLA in ABS filamenta. Idealna kombinacija trdnosti in fleksibilnosti. Dobre mehanske lastnosti.

Nakup 3D printerja vam lahko olajša marsikatero delo, vendar se morate prej zastaviti več vprašanj, da boste našli pravi 3D printer zase:

- Potrebe in cilji

- Tip 3D printerja

- Volumen 3D printanja

- Kompatibilni materiali (kakšne izdelke boste printali?)

- Predznanje

- Proračun (“budget”)

Več o korakih pred nakupom 3D printerja lahko izveste v tukaj.

Tukaj so najbolj razširjene tehnologije 3D printanja:

- Fused Deposition Modeling (FDM): najbolj priljubljena tehnologija 3D tiskanja, kjer 3D printer preko šobe nanaša filament plast za plastjo.

- Stereolitografija (SLA): uporablja laser za strjevanje tekoče smole.

- Selektivno lasersko sintranje (SLS): uporablja laser za sintranje materiala v prahu.

- Digitalna Light Processing (DLP): uporablja svetlobni projektor za strjevanje tekoče smole.

- Material Jetting (MJ): uporablja brizgalne tiskalne glave za brizganje tekočih fotopolimerov na gradbeno platformo plast za plastjo, da ustvari predmet.

- Direct Energy Deposition (DED): uporablja usmerjen vir energije (npr. laser ali elektronski žarek) za taljenje in odlaganje materiala.

Vse tehnologije 3D printanja imajo svoje prednosti in omejitve.